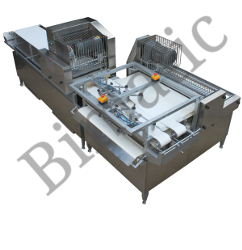

The dough flattener is a very precise sheeting machine. It is designed to transform the fermented dough balls into oval flat chips at 1st stage and into equal circular flat chips at 2nd stage to give the required dough shape and diameter undergoing minimum amount of flour.

Features:

It consists of special food grade Felt Belt and PVC Belts. It is relatively silent in operation. It is equipped with two stainless steel flour sifters and pressing cylinder to press the dough and ensure the uniform distribution of flour on loaf. In-addition to flour drawers to collect flour residues and to prevent flour from falling on ground and to re-use it Furthermore; special regulators were implemented to calibrate and control the thickness and diameter of dough. The flattening cylinders are made of hard chrome compatible with the world of health organization. . It operates via accurate electro / pneumatic system to shift the dough 90 degrees and transport it to the second block. It is controlled via constant speed motor to control the 1st stage of flattening process with another variable speed motor to control the 2nd stage of flattening process monitored by variable inverter system to control the production rate. The machine can be upgraded; due to demand, to be fully stainless steel or to be equipped with extra flour sifter and pressing cylinder and with CE safety and protection features.

| Output | Model |

Length (Cm) A |

Width (Cm) B |

Height (Cm) C |

Weight (Kg) |

Power supply (V A C) |

Cycle (Hz) |

Motor (HP) |

Total Power Consumption (KW-KVA) |

| Single | DF1 | 220 | 95 | 185 | 600 | 190-380 | 50-60 | 1+1 | 3.0-3.75 |

| Double | DF2-60 | 260 | 130 | 185 | 650 | 190-380 | 50-60 | 2 | 3.0-3.75 |

| DF2-80 | 280 | 160 | 185 | 900 | 190-380 | 50-60 | 2+2 | 4.0-4.75 | |

| Triple | DF3 | 280 | 170 | 185 | 1000 | 190-380 | 50-60 | 2+2 | 4.5-5.62 |

| Quadruple | DF4 | 300 | 180 | 185 | 1100 | 190-380 | 50-60 | 2+2 | 5.0-6.25 |

| Octa | DF8 | 320 | 190 | 185 | 1200 | 190-380 | 50-60 | 2+2 | 5.0-6.25 |

|