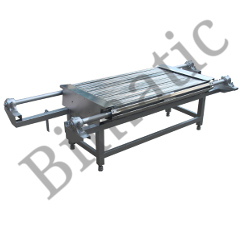

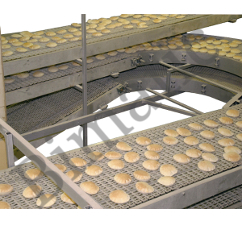

The Cooling Conveyors are designed to cool down and transport the baked loaves coming out from baking oven to packaging table. The length of the conveyors depends on the given layout and the available space as well as the type of production line and purpose.

Features:

Composed of aluminum straight conveyor’s frame and coated steel curves. The width of the cooling conveyors varies to be adequate with the production line. Belts move straight with 90 or 180 degree curves, or as required. The curves of the conveyor are found to be normal or opposed in size and shape. The belts are made with fiber web in a professional way to maintain chain tensions and minimize the stretching of the belt. It is relatively silent in operation. The fixation of the cooling unit could be either on ground spiral form or layered form, or hanged to the ceiling to benefit from the space beneath it. It is controlled via variable speed motors and variable inverter system to control the cooling process from external electric control panel that is mounted either on wall or on stand. The machine can be upgraded; due to demand, to be stainless steel curves frame and stands or to increase cooling process as well as to be equipped with CE safety and protection features.

| Model |

Length (Cm) A |

Width (Cm) B |

Height (Cm) C |

Weight (Kg) |

Power supply (V A C) |

Cycle (Hz) |

Motor (HP) |

Total Power Consumption (KW-KVA) |

| BCC50 | 3500 | 50 | 16 | 800 | 190-380 | 50-60 | 5*0.5 | 2.5-3.15 |

| BCC60 | 3500 | 60 | 16 | 1000 | 190-380 | 50-60 | 5*0.5 | 2.5-3.15 |

| BCC80 | 4500 | 80 | 16 | 1300 | 190-380 | 50-60 | 6*0.5 | 3.0-3.75 |

| BCC100 | 4500 | 100 | 16 | 1500 | 190-380 | 50-60 | 7*0.5 | 3.5-4.38 |

| BCC120 | 4500 | 120 | 16 | 1700 | 190-380 | 50-60 | 7*0.5 | 3.5-4.38 |

|